General Properties

Environment Outdoor

Working temperature - 15°C - +40°C

Altitude Max 1500 o.s.l.

Fixing point By 4 holed ppainting

Motors torque Standard

three-phase electric torque motor, IP 55

torque 2, 3,4.5 , 6,8.5 Nm self-ventilated

(option servo-ventilated)

torque 10,12, 17, 22, 35 Nm servo-ventilated

Electric collector/stator Low voltage

, protection IP 65.

Power voltage from 690Vac, up to 400 A

Auxiliary and signals/can bus, up to 42 rings

mixed power + auxiliary/signals

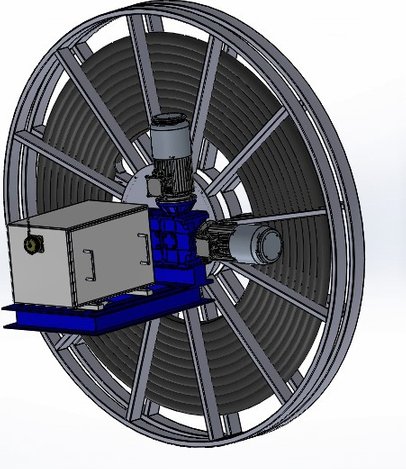

STANDARD CABLE REEL

Spool Until 800 mm in shaped sheet, red painted red More than 800 mm Ø, drawn steel plates, hot dip painting Internal hot painting steel band.

Gear box Support Aluminum or cast-iron high resistance casing red painted. Special casehardened and ground steel gears. High resistance steel shafts. Lubrication for life.

Electric Motor torque Voltage 230/400 Vac three-phase 50 Hz. Protection IP 55, Class H isolation. Die cast aluminum casing. Painted black.Stationing brake Disk with two braking surfaces (asbestos free). Protection timing case painted Bolts and Nuts

Electric collector

Outside the drum. Cast alloy bronze power rings, brass auxiliary rings, gold-plating or silver-plating signal rings.

Power and auxiliary copper-electro graphite brushes, Signals silver-graphite brushes. Plastic reinforced by fiber glass insulators.